-

Home

-

Products

-

Building & Decoration Tape

- Butyl waterproof tape

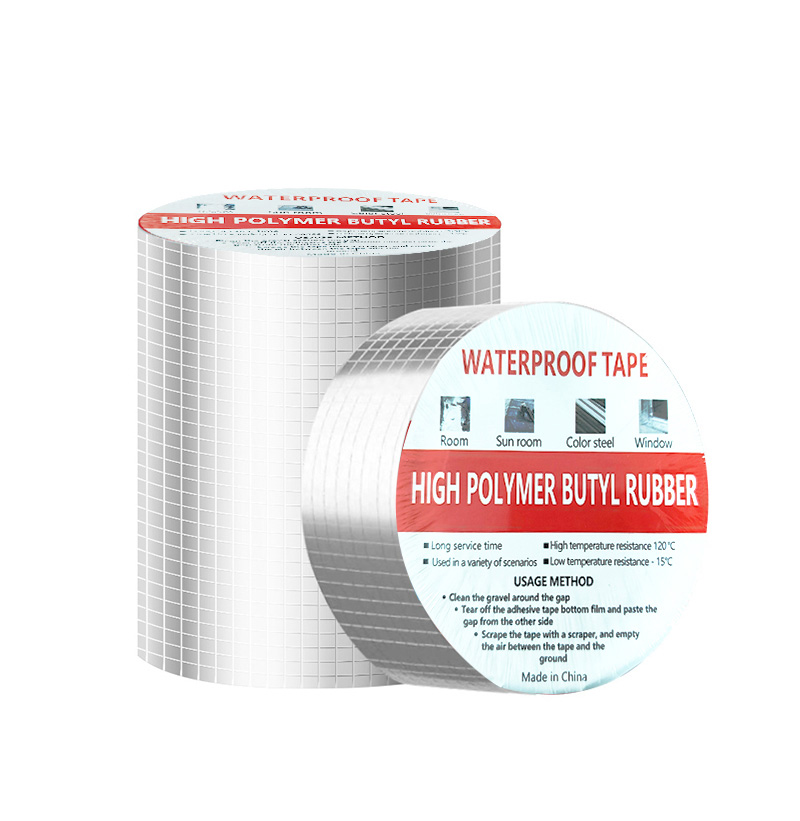

Butyl waterproof tape

I.Core Characteristics and Technical Advantages

1.Superior Sealing Performance

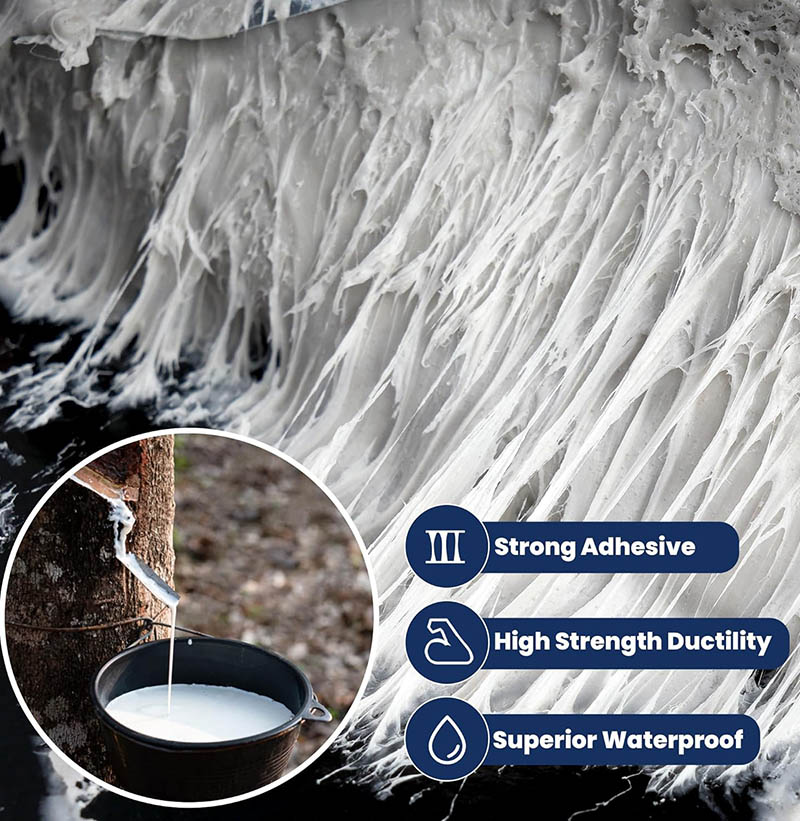

The product contains butyl rubber which has a dense molecular arrangement to achieve a water vapor transmission rate that approaches zero. The physical barrier function of the enhanced aluminum foil layer works together to prevent all moisture and gas from entering the system which results in better performance than asphalt-based or PVC tapes. The test results demonstrate that adhesive peel strength increased by more than 40% which guarantees long-term seal performance at essential points including roof joints and pipe interfaces.

2.Extreme Environmental Tolerance

The aluminum coating on this material provides excellent protection against weather conditions because it reflects all UV radiation that hits it. The built-in antioxidant formulation of butyl rubber enables it to resist temperature extremes which range from -40°C to 80°C. The system operates at a consistent level while handling different weather patterns which include salt spray exposure and high humidity and dry desert conditions. The material shows high chemical resistance because it protects against acid and base and solvent exposure which makes it appropriate for pipeline sealing in chemical areas and industrial plants.

Safe and Eco-Friendly: The product operates without solvents while following RoHS environmental standards. The product contains no toxic substances and produces no smells while allowing users to touch it directly to drinking water systems and sealed areas including RV interiors thus protecting human health.

3.Wide Substrate Compatibility

The product maintains strong initial tack and continues to provide durable bonding properties which enable it to attach to various surfaces including metals such as galvanized steel and aluminum and inorganic materials like concrete and masonry and tiles and glass and synthetic materials including PVC and EPDM rubber and fiberglass and porous substrates including wood and gypsum board. The solution resolves conventional tape restrictions which allow users to apply one tape solution for various applications.

II.Diverse Application Scenarios

The product serves multiple industries because of its adaptable design and dependable operation.

The company provides waterproofing system construction services which include fast roof crack repair and skylight and chimney base sealing and exterior wall joint waterproofing and basement leak repair. The system replaces conventional hot-melt application methods by achieving an 80% boost in operational efficiency.

The system maintains vehicles through its ability to fix RV/camper roof canopy damage and perform marine deck joint sealing and automotive window/door seal reinforcement which protects against both high-speed wind pressure and wave impacts.

The HVAC system requires three essential sealing measures which protect duct joints and vents from leaks and AC pipes from damage to achieve maximum energy efficiency.

The protection system for pipes includes three main components which consist of emergency PVC drain pipe crack repair and metal fitting anti-corrosion wrapping and irrigation system joint leak prevention to handle water pressure changes.

Outdoor Gear Assurance: The program includes tent seam reinforcement and canoe hull leak sealing and outdoor water container repair services which improve equipment performance under demanding outdoor conditions.

The DIY system enables users to perform three innovative tasks which include tarp securing and garden structure joining and household gap filling through its flexible design which does not require any specific tools.

III.Efficient Application Guide

The main purpose of butyl tape exists to provide users with both convenience and operational efficiency.

1.Surface Preparation: The process requires users to eliminate all surface dust and grease and loose particles which exist on the substrate. The surface needs to be both dry and free from dirt because no primer needs to be applied.

2.Cut and Apply: Trim tape to desired length, peel off release liner, and press directly onto target area.

3.Compress and Set: The user needs to apply hand or roller pressure to achieve complete tape-substrate contact especially at the tape edges.

4.Environmental Adaptation: The application area needs to stay away from powerful water currents during the first 24 hours after treatment because the mixture reaches its maximum strength at room temperature.

IV.Hongfu Tape Brand Assurance

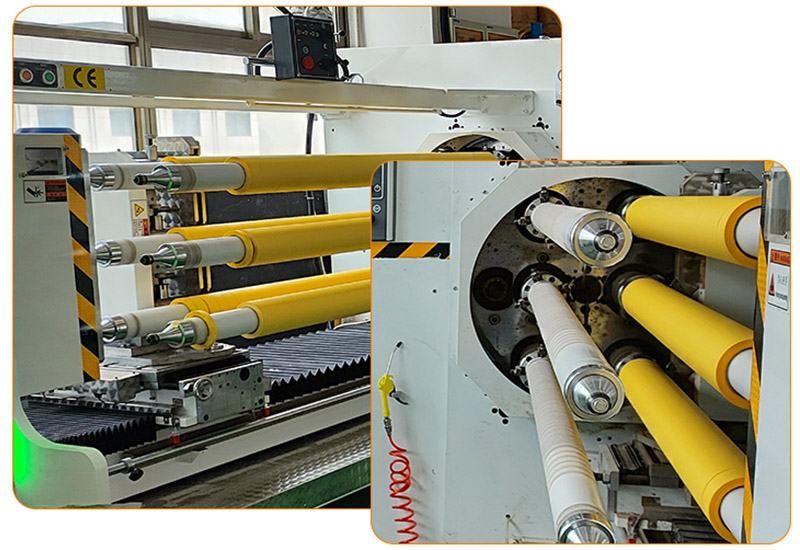

Hongfu Tape operates as a company which develops and produces sealing materials through its research and development and production activities. The production process of butyl tape involves using advanced polymer laboratories together with strict quality control systems which test each roll of product.

International Standard Certification: ISO 9001 Quality Management System, ASTM D1970 Waterproofing Test Standard.

The testing process for Extreme Environment Simulation involved running 3,000 hours of fast UV aging and 30 temperature cycles between -40°C and 80°C without any system breakdown.

The company performs continuous technology development which includes optimization of its Formulation and aluminum foil composite processes through worldwide user feedback to achieve 5th generation product development.

Conclusion

The scientific development of butyl tape creates new sealing standards which converts advanced material science into practical solutions for users. The product provides complete seal protection and follows military standards for durability while operating with simplicity which results in lower maintenance expenses and shorter maintenance periods that transform industry standards for seal durability. Hongfu will maintain its innovative approach to develop sealing products which surpass worldwide customer standards while protecting all essential elements.

-

Suitable for various occasions

Roof

Glasshouse

Color steel sheet roofing

Sunroom

Roof ridge gap

Edge of the sink

The edge of the exterior window

Exterior wall cracks

-

Strong Adhesive

High Strength Ductility

Superior Waterproof

-

Metal foil

Butyl rubber layer

Anti-stick liner

-

Product Features

Strong Adhesive

Waterproof

Toxic free

Extremely durable

Heat Resistant

UV Resistant

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Technical Assistance

Billing and Payment Services

Why Choose Us?